FERMENTERS AND BIOREACTORS DESIGN

There are many requirements that need to be met in the design of a large production scale fermentation facility. Aspects of design to be considered include design yield basis, operating schedule, media sterilization, fermenter and ancillary vessel design, piping systems, CIP/SIP and CGMP compliance. To be successful, a well thought-out and well-designed sanitary/sterile envelope is therefore crucial to the fermentation/biotech facility.

There are many requirements that need to be met in the design of a large production scale fermentation facility. Aspects of design to be considered include design yield basis, operating schedule, media sterilization, fermenter and ancillary vessel design, piping systems, CIP/SIP and CGMP compliance. To be successful, a well thought-out and well-designed sanitary/sterile envelope is therefore crucial to the fermentation/biotech facility.

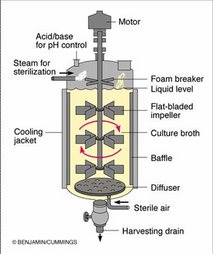

A fermenter is the set up to carry out the process of fermentation. The fermenters vary from laboratory experimental models of one or two litres capacity, to industrial models of several hundred litres capacity, which refers to the volume of the main fermenting vessel.

A bioreactor differs from a fermenter in that the former is used for the mass culture of plant or animal cells, instead of micro-organisms. The chemical compounds synthesised by these cultured cells, such as therapeutic agents, can be extracted easily from the cell biomass.

The design engineering and operational parameters of both fermenters and bioreactors are identical. With the involvement of micro-organisms as elicitors in some situations, the distinction between the two concepts is being gradually obliterated.

Functions/Requirements of Fermenter

4) Control the pH of the culture;

(Allman A.R., 1999: Fermentation Microbiology and Biotechnology)

Main parts of a Benchtop fermentor

1) Mechanical: drive motor, heater, pump, gas control, etc;

2) Vessel and accessories;

3) Peripheral equipment such as reagent bottles;

4) Instrumentation and sensors.

Types of Fermenter

1.

2.Air Lift Fermenter

3.1.

2.Air Lift Fermenter

4. Loop Fermenter

5.6. Packed Bed Fermenter

7.8. Tower Fermenter

9.

2 comments:

it's really knowledgable&helpful,thanx 4 posting it

This is very educational content and written well for a change. It's nice to see that some people still understand how to write a quality post! find best STL files

Post a Comment